The Gear Reduction starter is a compact

lightweight unit with high torque capacity.

The reduction gear is mounted on the same shaft as the pinion gear. Unlike the conventional starter, the magnetic switch plunger acts

directly on the pinion gear (not through a drive lever) to push the gear into mesh with the ring gear.

This type of starter was first used on the 1973 Corona MKII with the

4M, six cylinder engine. It is now used on most 1975 and newer

Toyotas. Ratings range from 0.8 KW on most Tercels and some older

models to as high as 2.5 KW on the diesel Corolla, Camry and Truck.

The cold−weather package calls for a 1.4 KW or 1.6 KW starter, while a

1.0 KW starter is common on other models.

The gear−reduction starter is the replacement starter for most conventional starters.

Clutch Operation:

1. During engine start, the starter pinion gear drives the engine’s

flywheel ring gear.

2. Once the engine fires, the ring gear almost instantly begins to turn

faster than the starter pinion gear. Over−speeding would damage

the starter motor if it were not immediately disengaged from the

pinion gear.

3. The clutch uses its wedged rollers and springs to disengage the

pinion shaft from the clutch housing (which turns with the motor

armature). This happens any time the pinion shaft tries to turn

faster than the clutch housing.

Ignition switch in ON:

1. Current no longer present at terminal 50," but the main switch

remains closed to allow current from terminal C" through the pull−in coil to the hold−in coil.

2. The magnetic fields in the two coils cancel each other, and the

plunger is pulled back by the return spring.

3. The high current to the motor is cut off and the pinion gear

disengages from the ring gear.

4. The armature has less inertia than the one in a conventional

starter. Friction stops it, so a brake is not needed.

Starter Motors - Construction

Armature coil wires − The coil wires in a PS starter armature are

square in cross−section.

• More compact winding than round cross−section wires

• Greater output torque

Surface commutator − The square shape of the armature conductors

allow the surface of the armature to act as a commutator.

Field coils − Conventional starters use field coils. PS type starters use

two types of permanent magnets instead:

• Main magnets

• Inter−polar magnets

The two types of magnets are arranged alternately inside the yoke.

• Work together to increase magnetic flux

• Allows shorter yoke

lightweight unit with high torque capacity.

The reduction gear is mounted on the same shaft as the pinion gear. Unlike the conventional starter, the magnetic switch plunger acts

directly on the pinion gear (not through a drive lever) to push the gear into mesh with the ring gear.

This type of starter was first used on the 1973 Corona MKII with the

4M, six cylinder engine. It is now used on most 1975 and newer

Toyotas. Ratings range from 0.8 KW on most Tercels and some older

models to as high as 2.5 KW on the diesel Corolla, Camry and Truck.

The cold−weather package calls for a 1.4 KW or 1.6 KW starter, while a

1.0 KW starter is common on other models.

The gear−reduction starter is the replacement starter for most conventional starters.

Clutch Operation:

1. During engine start, the starter pinion gear drives the engine’s

flywheel ring gear.

2. Once the engine fires, the ring gear almost instantly begins to turn

faster than the starter pinion gear. Over−speeding would damage

the starter motor if it were not immediately disengaged from the

pinion gear.

3. The clutch uses its wedged rollers and springs to disengage the

pinion shaft from the clutch housing (which turns with the motor

armature). This happens any time the pinion shaft tries to turn

faster than the clutch housing.

Ignition switch in ON:

1. Current no longer present at terminal 50," but the main switch

remains closed to allow current from terminal C" through the pull−in coil to the hold−in coil.

2. The magnetic fields in the two coils cancel each other, and the

plunger is pulled back by the return spring.

3. The high current to the motor is cut off and the pinion gear

disengages from the ring gear.

4. The armature has less inertia than the one in a conventional

starter. Friction stops it, so a brake is not needed.

Starter Motors - Construction

Armature coil wires − The coil wires in a PS starter armature are

square in cross−section.

• More compact winding than round cross−section wires

• Greater output torque

Surface commutator − The square shape of the armature conductors

allow the surface of the armature to act as a commutator.

Field coils − Conventional starters use field coils. PS type starters use

two types of permanent magnets instead:

• Main magnets

• Inter−polar magnets

The two types of magnets are arranged alternately inside the yoke.

• Work together to increase magnetic flux

• Allows shorter yoke

Fuel Pump

The fuel pump is mounted in the tank and immersed in fuel. The fuel cools and lubricates the pump. When current flows through the motor, the armature and impeller rotate. The impeller draws fuel in through a filter and discharges pressurized fuel through the outlet port. The fuel pump's pumping capacity is designed to exceed engine requirements. This insures that there will always be enough fuel to meet engine demands.

An outlet check valve, located in the discharge outlet, maintains a residual fuel pressure in the fuel system when the engine is off. This improves starting characteristics and reduces vapor-lock. Without residual fuel pressure, the system would have to be pressurized each time the engine was started and this would increase engine starting (cranking) time. When a hot engine

is shut off, fuel temperature in the lines around the engine increases. Keeping the system pressurized increases the boiling point of the fuel and prevents the fuel from vaporizing. A pressure relief valve will open if the fuel system becomes restricted. This is a safety device to prevent the fuel lines from rupturing and damage to the pump.

Jet Pump

The jet pump is an additional pump used when the fuel tank bottom is divided into two

chambers. Excess fuel flowing through the fuel return passes through a venturi. This creates a low pressure area around the venturi, and this action will draw the fuel out of Chamber B, and sends it into Chamber A

ON/OFF Control by Fuel Pump Switch

ON/OFF Control by Fuel Pump Switch

The fuel pump switch is found on older vehicles using a Vane Air Flow Meter. The air moves the vane when the engine is running closing the fuel pump switch. The following is an explanation of circuit operation.

Engine Start

When the engine is cranking, current flows from the IG terminal of the ignition switch to the L1 coil of the EFI main relay, turning the relay on. Current also flows from the ST terminal of the ignition switch to the L3 coil of the circuit-opening relay, turning it on to operate the fuel pump. After the engine starts, the cylinders begin drawing in air, causing the measuring plate inside the air flow meter to open. This turns on the fuel pump switch, which is connected to the

measuring plate, and current flows to the L2 coil of the circuit-opening relay.

Engine Running

After the engine starts and the ignition switch is turned from ST back to IG, current flowing to the L3 coil of the circuit-opening relay is cut off. However, current continues to flow to the L2 coil while the engine is running due to the fuel pump switch inside the air flow meter being on. As a result, the circuit-opening relay stays on, allowing the fuel pump to continue operating.

Engine Stopped

When the engine stops, the measuring plate completely closes and the fuel pump switch is turned off. This cuts off the flow of current to the L2 coil of the circuit-opening relay. As a result, the circuit-opening relay goes off and the fuel pump stops operating.

Two Speed Fuel Pump Control

Large displacement engines require a higher volume of fuel during starting and heavy load conditions than small displacement engines. High capacity fuel pumps are used to meet the demand, but they produce more noise and consume more power. To overcome these

disadvantages and increase pump life, a two speed fuel pump control is used.

Atmospheric Modulated Pressure Regulator

Atmospheric Modulated Pressure Regulator

The atmospheric modulated pressure regulator modifies fuel pressure with changes in

atmospheric pressure. A hose is connected from the pressure regulator to the air intake hose

between the air filter and throttle plate. Spring pressure and atmospheric pressure keep the

fuel pressure at a constant value, 226-265 kPa (38-44 psi). As air pressure changes, such as

climbing from low to high altitude, fuel rail pressure decreases because there is less force on

the diaphragm

High Temperature (Pressure Up) Fuel Pressure Control

High Temperature (Pressure Up) Fuel Pressure Control

Some engines are equipped with a high temperature fuel pressure control to prevent vapor lock for easier starting and better driveability. A three way VSV is connected to the fuel pressure

regulator vacuum line. Under normal conditions, the VSV is off and engine vacuum regulates the pressure regulator. If the engine is started when the coolant temperature is 85'C (185'F) or higher and the intake air temperature is above predetermined level, the ECM will turn on the VSV. Engine vacuum is closed off and atmospheric pressure is applied to the pressure

regulator diaphragm. This increases fuel pressure preventing vapor lock. Once the engine is started, the VSV may remain on for about 120 seconds.

Fuel Filters

Fuel Filters

Typically, there are two fuel filters in the fuel delivery system. The first filter is the fuel pump filter located on the suction side of the fuel pump. This filter prevents debris from damaging the fuel pump. The second filter, located between the pump and fuel rail, removes dirt and

contaminates from the fuel before it is delivered to the injectors. This filter removes extremely small particles from the fuel, the injectors require extremely clean fuel.

The filter may be located in the fuel tank as part of the fuel pump assembly or outside the tank in the fuel line leading to the fuel rail. The filter is designed to be maintenance-free with no required service replacement

Pulsation Damper

Pulsation Damper

The rapid opening and closing of the fuel injectors cause pressure fluctuations in the fuel rail. The result is that the amount of injected fuel will be more or less than the desired amount.

Mounted on the fuel rail, the pulsation damper reduces these pressure fluctuations. When pressure suddenly begins to increase the spring loaded diaphragm retracts slightly increasing fuel rail volume. This will momentarily prevent fuel pressure from becoming too high. When pressure suddenly begins to drop, the spring loaded diaphragm extends, slightly decreasing effective fuel rail volume. This will momentarily prevent fuel pressure from becoming too low. Not all engines require the use of a pulsation damper.

The screw mounted at the top of the damper provides an easy check for fuel system pressure.

When the screw is up it means the fuel rail is pressurized. Under most conditions, this check is adequate. The screw is nonadjustable and it is used to calibrate the damper at the factory.

Fuel Injection Operation

The fuel injector, when turned on by the ECM, atomizes and directs fuel into the intake manifold.

Fuel Injectors

There is one injector per cylinder mounted in the intake manifold before the intake valve(s). The

injectors are installed with an insulator/seal on the manifold end to insulate the injector from

heat and prevent atmospheric pressure from leaking into the manifold. The fuel delivery pipe

secures the injector. An O-ring between the delivery pipe and injector prevents the fuel from

leaking.

Different engines require different injectors. Injectors designed to pass a specified amount of fuel when opened. In addition, the number of holes at the tip of the injector varies with engines and model years. When replacing an injector it is critical that the correct injector be use.

The fuel pump is mounted in the tank and immersed in fuel. The fuel cools and lubricates the pump. When current flows through the motor, the armature and impeller rotate. The impeller draws fuel in through a filter and discharges pressurized fuel through the outlet port. The fuel pump's pumping capacity is designed to exceed engine requirements. This insures that there will always be enough fuel to meet engine demands.

An outlet check valve, located in the discharge outlet, maintains a residual fuel pressure in the fuel system when the engine is off. This improves starting characteristics and reduces vapor-lock. Without residual fuel pressure, the system would have to be pressurized each time the engine was started and this would increase engine starting (cranking) time. When a hot engine

is shut off, fuel temperature in the lines around the engine increases. Keeping the system pressurized increases the boiling point of the fuel and prevents the fuel from vaporizing. A pressure relief valve will open if the fuel system becomes restricted. This is a safety device to prevent the fuel lines from rupturing and damage to the pump.

Jet Pump

The jet pump is an additional pump used when the fuel tank bottom is divided into two

chambers. Excess fuel flowing through the fuel return passes through a venturi. This creates a low pressure area around the venturi, and this action will draw the fuel out of Chamber B, and sends it into Chamber A

ON/OFF Control by Fuel Pump Switch

ON/OFF Control by Fuel Pump Switch The fuel pump switch is found on older vehicles using a Vane Air Flow Meter. The air moves the vane when the engine is running closing the fuel pump switch. The following is an explanation of circuit operation.

Engine Start

When the engine is cranking, current flows from the IG terminal of the ignition switch to the L1 coil of the EFI main relay, turning the relay on. Current also flows from the ST terminal of the ignition switch to the L3 coil of the circuit-opening relay, turning it on to operate the fuel pump. After the engine starts, the cylinders begin drawing in air, causing the measuring plate inside the air flow meter to open. This turns on the fuel pump switch, which is connected to the

measuring plate, and current flows to the L2 coil of the circuit-opening relay.

Engine Running

After the engine starts and the ignition switch is turned from ST back to IG, current flowing to the L3 coil of the circuit-opening relay is cut off. However, current continues to flow to the L2 coil while the engine is running due to the fuel pump switch inside the air flow meter being on. As a result, the circuit-opening relay stays on, allowing the fuel pump to continue operating.

Engine Stopped

When the engine stops, the measuring plate completely closes and the fuel pump switch is turned off. This cuts off the flow of current to the L2 coil of the circuit-opening relay. As a result, the circuit-opening relay goes off and the fuel pump stops operating.

Two Speed Fuel Pump Control

Large displacement engines require a higher volume of fuel during starting and heavy load conditions than small displacement engines. High capacity fuel pumps are used to meet the demand, but they produce more noise and consume more power. To overcome these

disadvantages and increase pump life, a two speed fuel pump control is used.

Atmospheric Modulated Pressure Regulator

Atmospheric Modulated Pressure RegulatorThe atmospheric modulated pressure regulator modifies fuel pressure with changes in

atmospheric pressure. A hose is connected from the pressure regulator to the air intake hose

between the air filter and throttle plate. Spring pressure and atmospheric pressure keep the

fuel pressure at a constant value, 226-265 kPa (38-44 psi). As air pressure changes, such as

climbing from low to high altitude, fuel rail pressure decreases because there is less force on

the diaphragm

High Temperature (Pressure Up) Fuel Pressure Control

High Temperature (Pressure Up) Fuel Pressure ControlSome engines are equipped with a high temperature fuel pressure control to prevent vapor lock for easier starting and better driveability. A three way VSV is connected to the fuel pressure

regulator vacuum line. Under normal conditions, the VSV is off and engine vacuum regulates the pressure regulator. If the engine is started when the coolant temperature is 85'C (185'F) or higher and the intake air temperature is above predetermined level, the ECM will turn on the VSV. Engine vacuum is closed off and atmospheric pressure is applied to the pressure

regulator diaphragm. This increases fuel pressure preventing vapor lock. Once the engine is started, the VSV may remain on for about 120 seconds.

Fuel Filters

Fuel FiltersTypically, there are two fuel filters in the fuel delivery system. The first filter is the fuel pump filter located on the suction side of the fuel pump. This filter prevents debris from damaging the fuel pump. The second filter, located between the pump and fuel rail, removes dirt and

contaminates from the fuel before it is delivered to the injectors. This filter removes extremely small particles from the fuel, the injectors require extremely clean fuel.

The filter may be located in the fuel tank as part of the fuel pump assembly or outside the tank in the fuel line leading to the fuel rail. The filter is designed to be maintenance-free with no required service replacement

Pulsation Damper

Pulsation DamperThe rapid opening and closing of the fuel injectors cause pressure fluctuations in the fuel rail. The result is that the amount of injected fuel will be more or less than the desired amount.

Mounted on the fuel rail, the pulsation damper reduces these pressure fluctuations. When pressure suddenly begins to increase the spring loaded diaphragm retracts slightly increasing fuel rail volume. This will momentarily prevent fuel pressure from becoming too high. When pressure suddenly begins to drop, the spring loaded diaphragm extends, slightly decreasing effective fuel rail volume. This will momentarily prevent fuel pressure from becoming too low. Not all engines require the use of a pulsation damper.

The screw mounted at the top of the damper provides an easy check for fuel system pressure.

When the screw is up it means the fuel rail is pressurized. Under most conditions, this check is adequate. The screw is nonadjustable and it is used to calibrate the damper at the factory.

Fuel Injection Operation

The fuel injector, when turned on by the ECM, atomizes and directs fuel into the intake manifold.

Fuel Injectors

There is one injector per cylinder mounted in the intake manifold before the intake valve(s). The

injectors are installed with an insulator/seal on the manifold end to insulate the injector from

heat and prevent atmospheric pressure from leaking into the manifold. The fuel delivery pipe

secures the injector. An O-ring between the delivery pipe and injector prevents the fuel from

leaking.

Different engines require different injectors. Injectors designed to pass a specified amount of fuel when opened. In addition, the number of holes at the tip of the injector varies with engines and model years. When replacing an injector it is critical that the correct injector be use.

Техническое обслуживание автомобиля , Wartung Fahrzeug,L'entretien des véhicules,Manutenzione dei veicoli,صيانة المركبات.,维修车辆。

STAT

Recent Posts

Blog Archive

-

▼

2010

(39)

-

▼

ธันวาคม

(10)

- Toyota Starter

- Fuel Injector Toyota

- Instrument Panel J/B Inner Circuit Toyota Yaris

- ECU Engine control Toyota Yaris

- Transaxle and transmission Honda Civic

- Intake Manifold/Exhaust system Honda civic (1984)

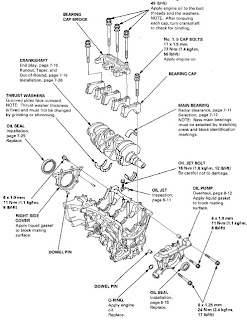

- Engine Lubrication Honda Civic (1984)

- Engine Honda Civic (1984)

- Camshaft/Rocker Arms and Camshaft/Pulley Honda Civ...

- Cylinder head Honda Civic 84 (ฝาสูบ)

-

▼

ธันวาคม

(10)