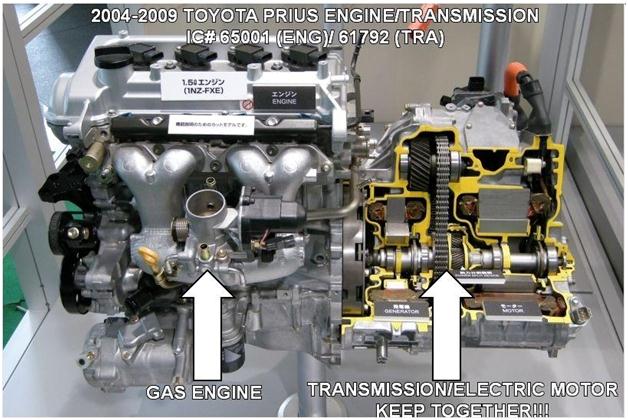

MG 1 (Motor-Generator 1) will be responsible for the production of electricity, feeding it with the battery. Including the power to enter the MG 2 with

MG 2 (Motor-Generator 2) force is acting in conjunction with the engine spinning drive shaft. The torque is higher than that will help drive is very powerful, soft and creamy as when shut and drive by while braking MG 2 this will be converted to a General Operator for electricity returned. The battery as gum Science.

In the gear set is a CVT: Continuously Variable Transmission has the ability to transform ratio independently. The computer control system. To organize forms of energy that is used by the engine or electric motor. Although HSD oil tank runs out, it also helps you move to another 1-2 miles to take you to the gas station.

The drive shaft is a gear installed in it. "To organize the torque of the motor and the engine by MG 2 (in the manual indicates that the MG-T or Torque) will be installed on the drive shaft. For extra torque to the drive. The drive shaft ends with a set PSD: Power Split Device installed on the one side is connected to the engine. The other side is connected directly to the MG 1 (or MG-S: Speed in the manual) to adjust the speed of the wheels to the speed of the engine and MG 1 sure enough by MG 1 is also used to absorb the difference between the vehicle speed. And around the machine as well.

The system will vary depending on the needs of speed and torque to be used. Can be divided as follows.

Low Gear, while accelerating the speed to low. Engine will not have role But if the motor MG 1 to serve as input to generate electricity MG 2, then twisting force to the spinning drive shaft again.

High Gear at the speed of movement. RPM slower than the speed of the wheels. But when you want to accelerate to overtake MG 1 MG 2 is acting as assistant immediately.

Reverse Gear No reverse gear in the system. But will rely on negative power delivered to the MG 2 instead.

Silent Operation mode, the engine does not rely in any way. The power to enter a single MG 2.

Regenerative Braking, which is positioned to take power from the MG 2 is a generation change, while slow-speed router. Fed back to the battery also contributes to increase braking force also.

compression Braking by HSD is a special gear system, which will replace existing automatic transmissions. For helping to brake in time or on steep downhill. The system adjusts the Regenerative Braking is, but when the system detects that the battery charging and braking excessively The system will change to Compression Braking is automatically distributed to the strength of MG 2 MG 1 again.

Volvo s40 Superproduction

ตอนนี้วอลโว่ S40 รุ่น C30, และ V50 กับเกียร์อัตโนมัติกับ turbodiesel สองลิตร ส่ง Powershift ใหม่เป็นหกความเร็ว มีคลัตช์เปียกคู่ที่ให้เทียบเท่ากับการเปลี่ยนมาใช้เกียร์อัตโนมัติแบบเดิมในขณะที่ประสิทธิภาพเทียบเท่ากับคู่มือ นอกจากนี้ Power Shift เชื้อเพลิงอย่างมีนัยสำคัญน้อยกว่าเกียร์อัตโนมัติทั่วไป Power Shift เป็นรุ่นปี 2009 ของสวีเดน

ตามที่ได้รายงานก่อนหน้านี้กระปุกเกียร์ Powershift วอลโว่วอลโว่คาร์ที่พัฒนาขึ้นโดยความร่วมมือกับพันธมิตรในการส่งผ่านของ Getrag Powershift ดำเนินการในหลักการเป็นสองเกียร์คู่มือขนาน มีคลัตช์เปียกคู่ที่ทำงานเป็นอิสระจากกัน หนึ่งคลัทช์ควบคุมเกียร์แปลก (1, 3, 5 และกลับรายการ) และคลัทช์ที่สองควบคุมอัตราส่วนแม้ (2, 4, 6) สอง clutches ดำเนินการอีกวิธีหนึ่งที่มีส่วนร่วมหนึ่งในขณะที่อื่น ๆ disengages

ซึ่งหมายความว่าในขณะที่เครื่องยนต์ได้รับอำนาจเต็มและแรงผลักดันสูงสุดในเกียร์แรก, เกียร์สองจะอยู่ในโหมดสแตนด และเฟืองเกียร์ที่สองที่สามเมื่อได้รับการเปิดใช้งานเป็น readied, และอื่น ๆ นี้ ส่งเสริมพลังงานน้ำท่วมอย่างต่อเนื่องโดยไม่หยุดชะงักหรือการสูญเสียใด ๆ แรงบิดส่งผลให้การเปลี่ยนแปลงอย่างรวดเร็วและเรียบขณะที่ยังคงเร่งตลอด กระบวนการแลกเปลี่ยน

นอกจากการเปลี่ยนแปลงความสะดวกสบายและประสิทธิภาพสูง Powershift ส่วนช่วยในการสิ้นเปลืองน้ำมันเชื้อเพลิงลดลงอย่างเห็นได้ชัด

-- ตามการวัดของเรา Powershift มีส่วนช่วยในการประหยัดน้ำมันเชื้อเพลิงประมาณแปดร้อยละเมื่อเทียบกับเกียร์ อัตโนมัติแบบเดิม,"says Magnus Jonsson, รองประธานอาวุโสฝ่ายวิจัยและพัฒนา, วอลโว่คาร์คอร์ปอเรชั่น

-- และมันเป็นพลังสำคัญในการล่าเพื่อลดผลกระทบด้านลบต่อสิ่งแวดล้อม, ยังคง Jonson

Powershift ทำงานอยู่บนพื้นฐานของเทคโนโลยีในการส่งคู่มือ, มีความแตกต่างที่สองคลัตช์เปียกมีการเชื่อมโยงกับเพลาแต่ละอินพุทของตัวเอง เพลาหมุนหนึ่งภายในอื่น ๆ การควบคุมภายในของเพลาส่งออกของเกียร์ 1, 3, 5 และกลับในขณะที่ด้านนอกควบคุมการส่งออกของเพลาเกียร์ 2, 4 และ 6 ฟังก์ชั่นคลัชจะดำเนินการโดยหน่วยควบคุมไฮโดรลิกไฟฟ้าที่มีลักษณะการที่คลัทช์เป็นหนึ่งในขณะที่อื่น ๆ ปิดเปิดและในทางกลับกัน

แต่ละคนชอบฟังก์ชั่นคลัชลื่นคลัช ลูกสูบผลักดันให้จำนวนของแผ่นคลัทช์ต่อกันและล็อคเข้าด้วยกันผ่านแรงเสียดทานผลลัพธ์

Powershift ให้ขับรถเกียร์อัตโนมัติที่อนุญาตให้เปลี่ยนเกียร์แบบเรียงลำดับเช่นเดียวกับการส่ง Geartronic ของวอลโว่ ความแตกต่างที่มี Powershift ส่งคู่มือแม้จะไม่มีเวลาหรือพลังงานสูญเสีย

ตั้งแต่ Powershift ซึ่งแตกต่างจากเกียร์อัตโนมัติแบบเดิมไม่ต้องแปลงแรงบิด, เกียร์ดาวเคราะห์หรือคลัตช์เปียกหลายนอกจากนี้ยังมีการสูญเสียที่พวกเขาเกิด แรงบิดเพิ่ม

ขอขอบคุณที่ใช้คลัตช์คู่เปียกสามารถ Powershift ส่งและแรงบิดสูงมีข้อ จำกัด ไม่เป็นหลักในการแลกเปลี่ยน ซึ่งจะทำให้พันธมิตรที่เหมาะกับเครื่องยนต์ดีเซลที่ทันสมัยและมีประสิทธิภาพ

รุ่นของ Powershift ที่วอลโว่ตอนนี้เปิดตัวเป็นไดเมนชันเพื่อจัดการกับแรงบิด 450 นิวตันเมตรของ วอ ลโว่ C30 ใน, S40 และ V50 ที่มีการเปลี่ยนแปลงอำนาจดีเซลเทอร์โบสี่สูบ 2.0 ลิตรที่มีการส่งออกของ 136 แรงม้าและแรงบิด 320 นิวตันเมตรของ

-- ด้วย Powershift ตอนนี้เราสามารถนำเสนอเกียร์อัตโนมัติกับดีเซลลิตรสองเรา"Magnus Jonsson กล่าวว่า

-- และจะไม่เกียร์อัตโนมัติ สิ้นเปลืองน้ำมันเชื้อเพลิงต่ำกว่าความสะดวกสบายที่เพิ่มขึ้นและมีประสิทธิภาพสูงกว่าเสียงเหมือนสมการเป็นไปไม่ได้ แต่ด้วย Powershift เราสามารถแสดงให้เห็นว่ามันเป็นไปได้อย่างสมบูรณ์แบบ

The engine is a four-cylinder two-liter engine. The regulations of the ERC allows an engine capacity of up to 2000 cc engine. Apart from this restriction so may not turbo or compressor used. The engine must be mounted in original position and torpedo the road must not be modified. The top is modified and the cams are as old JTCC reglmentet. In addition, as is the exhaust manifold modified and completed with a 2.5 inch exhaust system with race catalyst. The oil reservoir is modified with an oil trap.

The suction is the original single throttle but luftbox and air filters are changed for better airflow to the top. Vattenkylet is original and completed with a three-row oil cooler. Alternator bracket is changed to move the weight down. The spark plugs are hard racing pins. Cable harness is custom designed and the control system is specially built for this car.

The gearbox is a five-speed dogringlåda from Tractive with differential lock adapted for the M56 gearbox. The gearbox was initially built for S60 Challenge cars and have therefore been extensively tested. A sachs clutch and flywheel helped transmit power to the gearbox. The original drive shafts used in the right hand slightly modified.

Now, the Volvo C30, S40 and V50 models with automatic transmission with two-liter turbodiesel. The new Powershift transmission is a six-speed. It has twin wet clutches that provide a switching equivalent to a conventional automatic transmission, while performance on a par with a manual. In addition, Power Shift significantly less fuel than a conventional automatic transmission. Power Shift is the model year 2009 to Sweden.

As previously reported, Volvo Powershift gearbox developed by Volvo Cars in cooperation with its transmission partner Getrag. Powershift operates in principle as two parallel manual gearboxes. It has twin wet clutches that work independently of each other. The one clutch regulates the odd gears (1, 3, 5 and reverse) and the second clutch regulates the even ratios (2, 4, 6). The two clutches operate alternately, with one engaging while the other disengages.

This means that while the engine gets full power and maximum thrust in first gear, second gear is placed in standby mode. And when second gear has been activated third gear is readied, and so on. This promotes a continuous flood of power without interruption or any torque loss, resulting in very fast and smooth changes while maintaining acceleration throughout the exchange process.

In addition to changing comfort and high performance, Powershift contributes to noticeably lower fuel consumption.

- According to our measurements, Powershift contributes to a fuel saving of about eight percent, when comparing with a conventional automatic transmission, "says Magnus Jonsson, Senior Vice President, Research & Development, Volvo Car Corporation.

- And it is an important power in the hunt for a reduced negative impact on the environment, continues to Jonson.

Powershift function is based on the technology in a manual transmission, with the difference that the two wet clutches are each linked with their own input shaft. One shaft spins inside the other. The internal control of the output shaft of the gear 1, 3, 5 and reverse, while the outer regulates the output shaft of gear 2, 4 and 6. The clutch function is operated by an electro-hydraulic control unit that ensures that one clutch is shut while the other is open and vice versa.

Each clutch functions like a slip clutch. A piston pushes a number of clutch plates against each other and locks them together through the resultant friction.

Powershift gives the driver an automatic transmission that permits sequential gear changes, just like with Volvo's Geartronic transmission. The difference is that with Powershift even manual transmission is no time or power losses.

Since Powershift, unlike a conventional automatic transmission, does not need a torque converter, planetary gears or multiple wet clutches, there is also the added torque losses they incur.

Thanks to the use of twin wet clutches can Powershift transmission and high torque has essentially no restrictions on the interchange. This makes it an ideal partner with modern, powerful diesel engines.

The version of Powershift that Volvo is now launching is dimensioned to handle torque of 450 Nm. In the Volvo C30, S40 and V50 power shift with the four-cylinder turbo diesel of 2.0 liters with an output of 136 hp and 320 Nm of torque.

- With Powershift we can now offer an automatic transmission with our two-liter diesel, "says Magnus Jonsson.

- And it is not the automatic transmission. Lower fuel consumption, increased comfort and higher performance sounds like an impossible equation. But with Powershift we can show that it is perfectly possible.

ตอนนี้วอลโว่ S40 รุ่น C30, และ V50 กับเกียร์อัตโนมัติกับ turbodiesel สองลิตร ส่ง Powershift ใหม่เป็นหกความเร็ว มีคลัตช์เปียกคู่ที่ให้เทียบเท่ากับการเปลี่ยนมาใช้เกียร์อัตโนมัติแบบเดิมในขณะที่ประสิทธิภาพเทียบเท่ากับคู่มือ นอกจากนี้ Power Shift เชื้อเพลิงอย่างมีนัยสำคัญน้อยกว่าเกียร์อัตโนมัติทั่วไป Power Shift เป็นรุ่นปี 2009 ของสวีเดน

ตามที่ได้รายงานก่อนหน้านี้กระปุกเกียร์ Powershift วอลโว่วอลโว่คาร์ที่พัฒนาขึ้นโดยความร่วมมือกับพันธมิตรในการส่งผ่านของ Getrag Powershift ดำเนินการในหลักการเป็นสองเกียร์คู่มือขนาน มีคลัตช์เปียกคู่ที่ทำงานเป็นอิสระจากกัน หนึ่งคลัทช์ควบคุมเกียร์แปลก (1, 3, 5 และกลับรายการ) และคลัทช์ที่สองควบคุมอัตราส่วนแม้ (2, 4, 6) สอง clutches ดำเนินการอีกวิธีหนึ่งที่มีส่วนร่วมหนึ่งในขณะที่อื่น ๆ disengages

ซึ่งหมายความว่าในขณะที่เครื่องยนต์ได้รับอำนาจเต็มและแรงผลักดันสูงสุดในเกียร์แรก, เกียร์สองจะอยู่ในโหมดสแตนด และเฟืองเกียร์ที่สองที่สามเมื่อได้รับการเปิดใช้งานเป็น readied, และอื่น ๆ นี้ ส่งเสริมพลังงานน้ำท่วมอย่างต่อเนื่องโดยไม่หยุดชะงักหรือการสูญเสียใด ๆ แรงบิดส่งผลให้การเปลี่ยนแปลงอย่างรวดเร็วและเรียบขณะที่ยังคงเร่งตลอด กระบวนการแลกเปลี่ยน

นอกจากการเปลี่ยนแปลงความสะดวกสบายและประสิทธิภาพสูง Powershift ส่วนช่วยในการสิ้นเปลืองน้ำมันเชื้อเพลิงลดลงอย่างเห็นได้ชัด

-- ตามการวัดของเรา Powershift มีส่วนช่วยในการประหยัดน้ำมันเชื้อเพลิงประมาณแปดร้อยละเมื่อเทียบกับเกียร์ อัตโนมัติแบบเดิม,"says Magnus Jonsson, รองประธานอาวุโสฝ่ายวิจัยและพัฒนา, วอลโว่คาร์คอร์ปอเรชั่น

-- และมันเป็นพลังสำคัญในการล่าเพื่อลดผลกระทบด้านลบต่อสิ่งแวดล้อม, ยังคง Jonson

Powershift ทำงานอยู่บนพื้นฐานของเทคโนโลยีในการส่งคู่มือ, มีความแตกต่างที่สองคลัตช์เปียกมีการเชื่อมโยงกับเพลาแต่ละอินพุทของตัวเอง เพลาหมุนหนึ่งภายในอื่น ๆ การควบคุมภายในของเพลาส่งออกของเกียร์ 1, 3, 5 และกลับในขณะที่ด้านนอกควบคุมการส่งออกของเพลาเกียร์ 2, 4 และ 6 ฟังก์ชั่นคลัชจะดำเนินการโดยหน่วยควบคุมไฮโดรลิกไฟฟ้าที่มีลักษณะการที่คลัทช์เป็นหนึ่งในขณะที่อื่น ๆ ปิดเปิดและในทางกลับกัน

แต่ละคนชอบฟังก์ชั่นคลัชลื่นคลัช ลูกสูบผลักดันให้จำนวนของแผ่นคลัทช์ต่อกันและล็อคเข้าด้วยกันผ่านแรงเสียดทานผลลัพธ์

Powershift ให้ขับรถเกียร์อัตโนมัติที่อนุญาตให้เปลี่ยนเกียร์แบบเรียงลำดับเช่นเดียวกับการส่ง Geartronic ของวอลโว่ ความแตกต่างที่มี Powershift ส่งคู่มือแม้จะไม่มีเวลาหรือพลังงานสูญเสีย

ตั้งแต่ Powershift ซึ่งแตกต่างจากเกียร์อัตโนมัติแบบเดิมไม่ต้องแปลงแรงบิด, เกียร์ดาวเคราะห์หรือคลัตช์เปียกหลายนอกจากนี้ยังมีการสูญเสียที่พวกเขาเกิด แรงบิดเพิ่ม

ขอขอบคุณที่ใช้คลัตช์คู่เปียกสามารถ Powershift ส่งและแรงบิดสูงมีข้อ จำกัด ไม่เป็นหลักในการแลกเปลี่ยน ซึ่งจะทำให้พันธมิตรที่เหมาะกับเครื่องยนต์ดีเซลที่ทันสมัยและมีประสิทธิภาพ

รุ่นของ Powershift ที่วอลโว่ตอนนี้เปิดตัวเป็นไดเมนชันเพื่อจัดการกับแรงบิด 450 นิวตันเมตรของ วอ ลโว่ C30 ใน, S40 และ V50 ที่มีการเปลี่ยนแปลงอำนาจดีเซลเทอร์โบสี่สูบ 2.0 ลิตรที่มีการส่งออกของ 136 แรงม้าและแรงบิด 320 นิวตันเมตรของ

-- ด้วย Powershift ตอนนี้เราสามารถนำเสนอเกียร์อัตโนมัติกับดีเซลลิตรสองเรา"Magnus Jonsson กล่าวว่า

-- และจะไม่เกียร์อัตโนมัติ สิ้นเปลืองน้ำมันเชื้อเพลิงต่ำกว่าความสะดวกสบายที่เพิ่มขึ้นและมีประสิทธิภาพสูงกว่าเสียงเหมือนสมการเป็นไปไม่ได้ แต่ด้วย Powershift เราสามารถแสดงให้เห็นว่ามันเป็นไปได้อย่างสมบูรณ์แบบ

The engine is a four-cylinder two-liter engine. The regulations of the ERC allows an engine capacity of up to 2000 cc engine. Apart from this restriction so may not turbo or compressor used. The engine must be mounted in original position and torpedo the road must not be modified. The top is modified and the cams are as old JTCC reglmentet. In addition, as is the exhaust manifold modified and completed with a 2.5 inch exhaust system with race catalyst. The oil reservoir is modified with an oil trap.

The suction is the original single throttle but luftbox and air filters are changed for better airflow to the top. Vattenkylet is original and completed with a three-row oil cooler. Alternator bracket is changed to move the weight down. The spark plugs are hard racing pins. Cable harness is custom designed and the control system is specially built for this car.

The gearbox is a five-speed dogringlåda from Tractive with differential lock adapted for the M56 gearbox. The gearbox was initially built for S60 Challenge cars and have therefore been extensively tested. A sachs clutch and flywheel helped transmit power to the gearbox. The original drive shafts used in the right hand slightly modified.

Now, the Volvo C30, S40 and V50 models with automatic transmission with two-liter turbodiesel. The new Powershift transmission is a six-speed. It has twin wet clutches that provide a switching equivalent to a conventional automatic transmission, while performance on a par with a manual. In addition, Power Shift significantly less fuel than a conventional automatic transmission. Power Shift is the model year 2009 to Sweden.

As previously reported, Volvo Powershift gearbox developed by Volvo Cars in cooperation with its transmission partner Getrag. Powershift operates in principle as two parallel manual gearboxes. It has twin wet clutches that work independently of each other. The one clutch regulates the odd gears (1, 3, 5 and reverse) and the second clutch regulates the even ratios (2, 4, 6). The two clutches operate alternately, with one engaging while the other disengages.

This means that while the engine gets full power and maximum thrust in first gear, second gear is placed in standby mode. And when second gear has been activated third gear is readied, and so on. This promotes a continuous flood of power without interruption or any torque loss, resulting in very fast and smooth changes while maintaining acceleration throughout the exchange process.

In addition to changing comfort and high performance, Powershift contributes to noticeably lower fuel consumption.

- According to our measurements, Powershift contributes to a fuel saving of about eight percent, when comparing with a conventional automatic transmission, "says Magnus Jonsson, Senior Vice President, Research & Development, Volvo Car Corporation.

- And it is an important power in the hunt for a reduced negative impact on the environment, continues to Jonson.

Powershift function is based on the technology in a manual transmission, with the difference that the two wet clutches are each linked with their own input shaft. One shaft spins inside the other. The internal control of the output shaft of the gear 1, 3, 5 and reverse, while the outer regulates the output shaft of gear 2, 4 and 6. The clutch function is operated by an electro-hydraulic control unit that ensures that one clutch is shut while the other is open and vice versa.

Each clutch functions like a slip clutch. A piston pushes a number of clutch plates against each other and locks them together through the resultant friction.

Powershift gives the driver an automatic transmission that permits sequential gear changes, just like with Volvo's Geartronic transmission. The difference is that with Powershift even manual transmission is no time or power losses.

Since Powershift, unlike a conventional automatic transmission, does not need a torque converter, planetary gears or multiple wet clutches, there is also the added torque losses they incur.

Thanks to the use of twin wet clutches can Powershift transmission and high torque has essentially no restrictions on the interchange. This makes it an ideal partner with modern, powerful diesel engines.

The version of Powershift that Volvo is now launching is dimensioned to handle torque of 450 Nm. In the Volvo C30, S40 and V50 power shift with the four-cylinder turbo diesel of 2.0 liters with an output of 136 hp and 320 Nm of torque.

- With Powershift we can now offer an automatic transmission with our two-liter diesel, "says Magnus Jonsson.

- And it is not the automatic transmission. Lower fuel consumption, increased comfort and higher performance sounds like an impossible equation. But with Powershift we can show that it is perfectly possible.

Техническое обслуживание автомобиля , Wartung Fahrzeug,L'entretien des véhicules,Manutenzione dei veicoli,صيانة المركبات.,维修车辆。